OUR BUSINESS

About forging of Kyoei

Forging is a manufacturing technique to form metals by heating and hammering them.

One of the major examples of forging is the making of Japanese swords.

At Kyoei Forging Works, we integrate traditional technological capability and up-to-date technology and facilities to manufacture items with complicated shapes, keeping strength as forged items. We manufacture a wide variety of machinery parts like conveying parts, auto parts, and large agricultural machinery parts. We offer our customers high quality products by conducting strict quality inspections multiple times.

POINT 01 Advanced forging technique and up-to-date facilities

We integrated the forging technique of 90 years and up-to-date technology and facilities.

POINT 02 We respond to a wide variety of requests

By forging by utilizing technology and facilities, we are available for complicated shapes thought to be difficult to make.

POINT 03 Quality management by multiple strict inspections

We conduct strict inspections multiple times to achieve high quality standard.

Product processing of forging items

Let us introduce the process of how one product is completed by forging. At Kyoei Forging Works, we start from designing the products and creating tooling, and with our accumulated technological capability and facilities, forging processing is conducted. Our processing department handles flexibly the shapes and sizes that are difficult to be handled done by forging. After conducting multiple strict inspections and finishing, high quality products are delivered to the customers.

Facilities of Kyoei Forging Works

At Kyoei Forging Works, we adopt the most advanced machinery and equipment to conduct high accuracy manufacturing. Please see our facilities that can do different types of works from designing and making molds to manufacturing.

About new factory

A hybrid forging factory, where friendliness to the environment of surrounding areas and productivity coexist

Forging noise is about the same level as engines of jet airplanes and its vibration corresponds to the seismic intensity of 4.

Our factory has special structure for specializing in suppressing noise and vibration by using airdrop hammer.

It is an innovative noise and vibration controled factory that is attracting attention both domestically and internationally.

List of facilities

-

Machining center

-

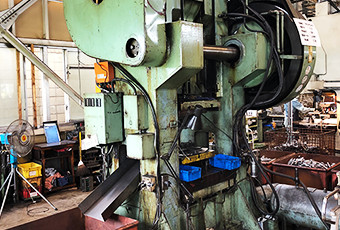

Crank press

-

Knuckle press

-

Air drop hammer

-

High frequency induction heating furnace

-

Automated warehouse system

List of facilities

| Type | Name | Specification | Number | Remarks |

|---|---|---|---|---|

| Forging | High speed airdrop hammer | N800P(3.0t) | 1 | NSC (Nittan Sakae Corporation) |

| High speed airdrop hammer | N550P(2.0t) | 1 | NSC (Nittan Sakae Corporation) | |

| High speed airdrop hammer | N500P(1.75t) | 1 | NSC (Nittan Sakae Corporation) | |

| High speed airdrop hammer | N350P(1.25t) | 2 | NSC (Nittan Sakae Corporation) | |

| Trimming press | 125~200t | 5 | NSC (Nittan Sakae Corporation) | |

| High frequency induction heating furnace | 200~350kw | 5 | Uchino | |

| Screw engine compressor | 150~165kw | 12 | Hokuetsu Industries | |

| Shearing press | 100t,200t | 2 | Endo, KS-TECH | |

| Molds | Vertical type milling cutter | #1 ½~#4 | 2 | Makino, OKK |

| Horizontal type milling cutter | #4 | 1 | OKK | |

| Numerical control milling cutter | #3 PRM3V, Rakuraku Mill | 1 | OKK | |

| Machining center | #5~#5 1/2 VM5Ⅲ,VM660R | 2 | OKK | |

| Numerical control electrical discharge machining | C4-M55K,C7-M55J | 2 | Mitsubishi Electric | |

| Numerical control wire electrical discharge machining | SP43,DU043 | 2 | Makino | |

| Sandblaster | MK-5 | 1 | FujiSS | |

| Vertical type machining center | V-55,V-56,V-56i | 3 | Makino | |

| Surface grinding machine | #2,#4 | 2 | Mitsui High-tec, Nikko | |

| Radial arm drill press | TRD-800C | 1 | TOA | |

| Tabletop drill press | KRDG-340FB | 1 | KIRA | |

| Automated warehouse system | ON-S-132P | 1 | Daifuku | |

| 3D CAD/CAM | EVC110,PC | 3 | Euklid | |

| 2D CAD/CAM | MYPAC, Compact CAM | 2 | Kuraki, Procast | |

| Processing | Automatic feeding drill press | ADF-410,KRDG-420P | 5 | Ashina, KIRA |

| Knuckle press | 300~600ton | 4 | Komatsu Industries | |

| Vertical type milling cutter | #3 | 26 | OKK | |

| Crank press | 70t~120t | 5 | Komatsu Industries | |

| Servo press | 150t | 1 | Amada | |

| Link processing machine | ZR-6P | 1 | Fujiya Seisakujo | |

| Inspection and finishing | Continuous magnetic particle inspection equipment | H-8 | 1 | Denshijiki Industry |

| Microscope (metallograph) | VHX-950F | 1 | Keyence | |

| Rockwell hardness tester | 3R | 1 | Imai Testing Machine | |

| Brinell hardness tester | NBH-3 | 1 | Nakai Precision Machinery | |

| Shot blast machine | 200~1200 | 4 | Sintokogio | |

| Corrosion inhibitor conveyor line | MZC, MLC TYPE | 6 | Mesh Giken | |

| Riveting machine | US series, MB-O/100 | 4 | Yoshikawa Iron Works, Techno Marushichi | |

| 3D measuring machine | Hand hold probe CMM XM-1500,YL-350 | 2 | Keyence | |

| 3D printer | 203(W)×203(D)×152(H)mm | 1 | Keyence | |

| The mobile pallet racking system | 468 Pallet | 1 | Daifuku |